Bioaltus Labs has a state-of- the art API manufacturing facility at Paithan, Aurangabad, Maharashtra. The plant is spread over a plot area of 45000 sq.ft.

The GMP Block shall be built with three key points in mind: Efficiency, Safety and Environment. Our compact, yet robust factory complex shall have all the key ingredients for a successful manufacturing unit. Our API manufacturing facilities shall be operated in accordance with cGMP guidelines as well as requirements of International Regulatory authorities such as the USFDA, EMEA, ANVISA, PMDA, KFDA, COFEPRIS.

The Flexible manufacturing infrastructure and multipurpose facilities will allow the expansion of product range and change in product mix in response to changes in the customer demand. It shall enable us catering to customer requirements ranging from Gram, Kilo level to Commercial production in multi tons.

Built to GMP requirements, our production lines uses the best of breed equipment including a fully qualified HVAC system including full control of temperature, humidity and room pressure which ensures the right environment for quality manufacturing.

The facilities at the plant includes

Our utilities shall be housed in a separate building –Utility Block to ensure that these critical aspects of the facility can be effectively maintained and serviced by our dedicated staff.

HVAC System comprising of 10 AHUs

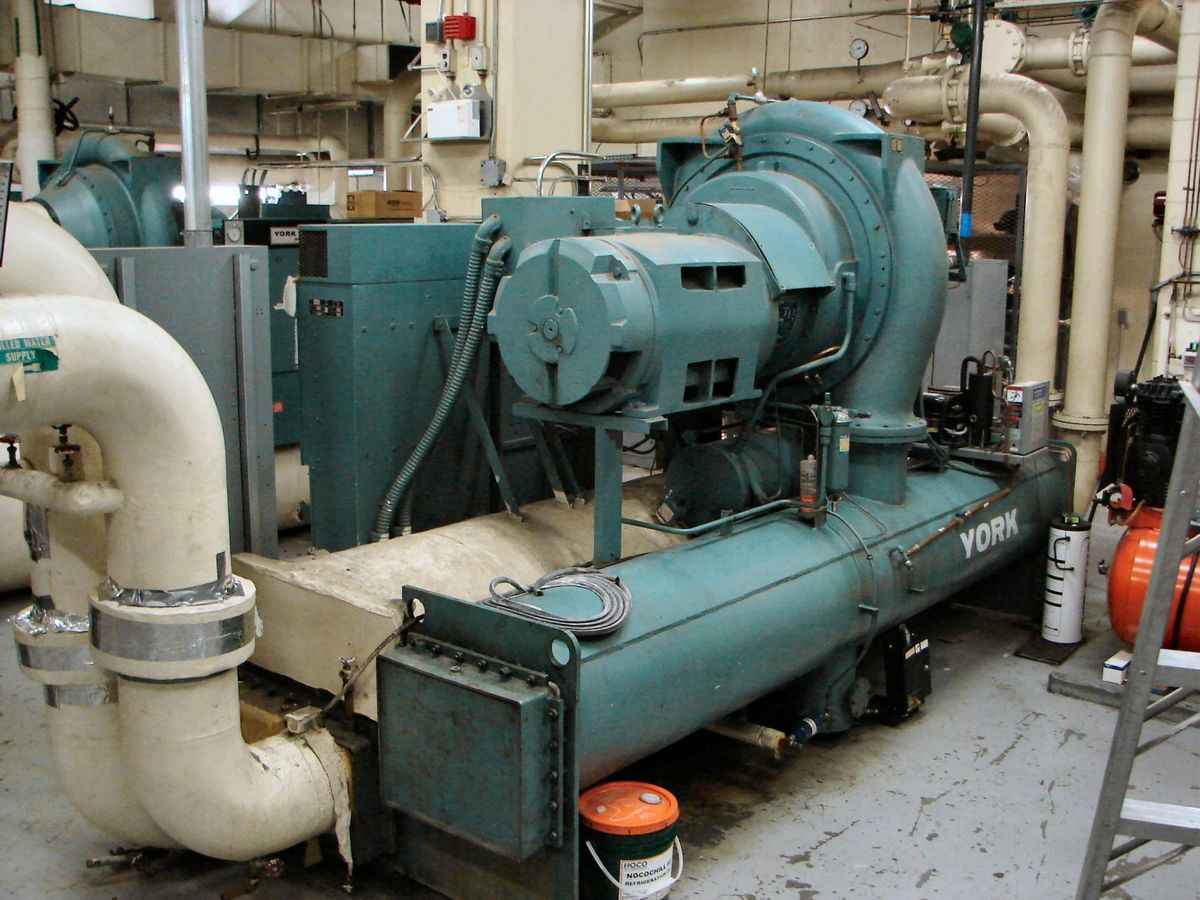

Chilling Unit

Boiler

Compressor (oil free)

Water Purification System

PLC controlled Purified Water System

HVAC System comprising with HEPA filters

Brine plant (-25°C )

Generator system

Thermic fluid system

Nitrogen distribution system for interstation

Our Quality Control Laboratory will be our advanced, accredited research facility, delivering end to end testing solutions of raw and processed material. Our facility will be geared to conduct high intensity quality control testing in both a Wet and Dry Analytical conditions. Our array of essential equipment for Chemical Analysis, Laboratory testing, Microbiology Laboratory, and Instrumental Analysis Laboratory include:

Our lab is staffed with trained and qualified analysts to oversee products in accordance with GLP and GMP standards and it is facilitated with:

It includes physical, chemical, and biological processes to remove physical, chemical and biological contaminants. Its objective is to produce a waste stream including solid waste suitable for discharge or reuse back into the environment. This includes below: